GFRP Rebar vs. TMT Rebar: Which Is Right for Your Project?

Introduction

Selecting the right reinforcement material is crucial for the success and durability of any construction project. Glass Fiber Reinforced Polymer (GFRP) rebars are increasingly competing with traditional Thermo-Mechanically Treated (TMT) steel bars, each offering distinct advantages and considerations.

Strength and Performance

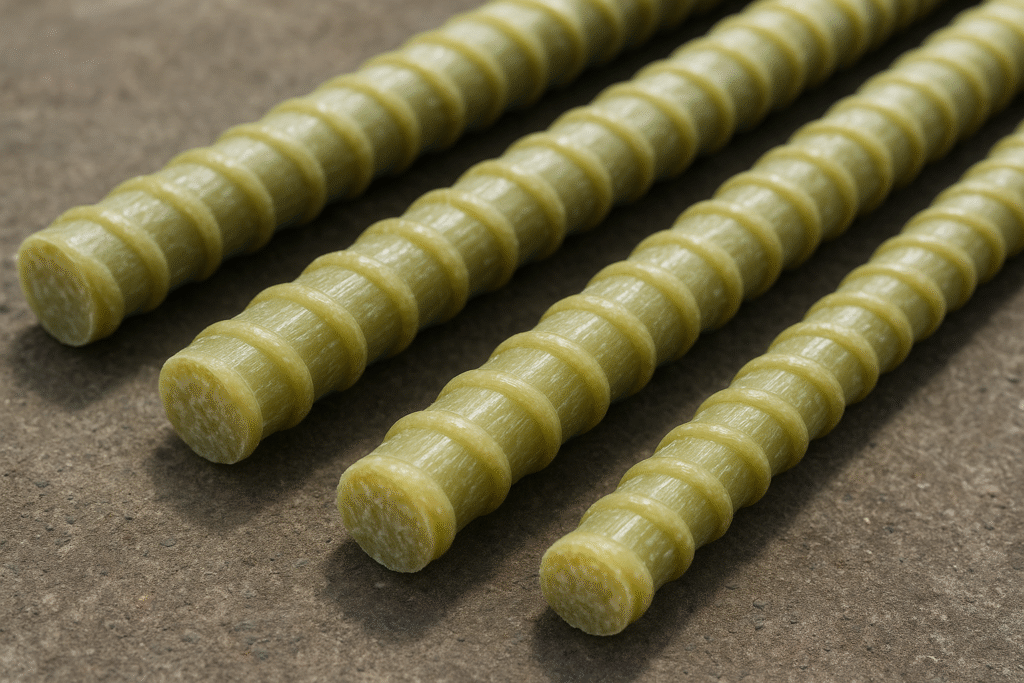

– GFRP Rebar: High tensile strength with excellent corrosion resistance, lightweight for easy handling.

– TMT Rebar: High yield strength with ductility and gradual deformation before failure, widely used for general concrete reinforcement.

Durability and Corrosion Resistance

– GFRP rebars do not corrode, ideal for marine, chemical, and saline environments.

– TMT rebars are susceptible to rust, which can compromise structural integrity over time.

Installation and Handling

– GFRP bars are lighter, reducing labor and transportation costs but require careful handling to avoid brittle failure.

– TMT bars are heavier but familiar to construction teams and offer flexibility during bending and tying.

Cost and Lifecycle Considerations

– GFRP rebars have a Lower cost upfront as well as Zero maintenance requiring virtually no corrosion-related repairs.

– TMT rebars are higher in cost and may also incur higher long-term costs due to corrosion and repair needs.

Which to Choose?

– For corrosion-prone environments, GFRP is the preferred choice.

– Hybrid approaches combining both may optimize cost and performance.